Chennai Viewpoint | AI Internet of Things wave of air compressor (next) air compressor practitioners must read

Release time:

2023-04-13

Internet of Things (IoT) is the third information technology revolution after computer, Internet and mobile communication network.

Internet of Things (IoT) is the third information technology revolution after computer, Internet and mobile communication network. The emergence of computer has changed the traditional way of computing, the emergence of Internet has reshaped the human lifestyle, and the application of IoT will completely change industrial manufacturing, agricultural production and people's daily life, and its application will profoundly affect industrial production, home life, transportation logistics and other aspects. At present, many important economies in the world have elevated the development of IoT to the level of national strategy.

The IoT tide has arrived

According to International Data Corporation (IDC) 2020, the global IoT market has been observed to grow at a CAGR of 20%. In addition, with the business integration of artificial intelligence (AI), big data and IoT technologies, the Industrial Internet of Things (IIoT) will gain more momentum, and its development trend can be seen in the tube of the air compressor industry. What are the specific uses of IoT in the air compressor industry?

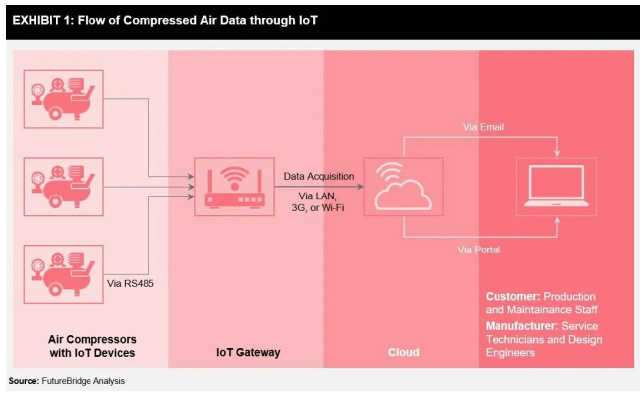

Schematic diagram of IOT data processing process of Chenn Air Compressor

| Real-time service & machine status overview end-users and manufacturers can monitor the parameters of air compressors in real time and perform real-time technical service accordingly.

| Historical data analysis The historical data collected back to the cloud will provide more accurate information for maintenance and after-sales personnel. These data can help service providers better understand and improve some important indicators, such as: Mean Time to Repair (MTTR), First Time Repair Rate, etc.

| Predictive maintenance, also known as predictive analysis, allows air compressor manufacturers to prevent unplanned compressor downtime by accessing performance data collected from compressors, helping users to detect technical failures of key compressor components in advance. Predictive analysis is inseparable from AI algorithms and machine learning. We all think AI is very profound, but in fact, in simple terms, it can be divided into three steps: first assume that the parameters collected back by the air compressor are X, we make up a program called f(x) inside the system, and we then make Y=f(x), when the result of Y and the past failure situation highly match, this Y, which is the result we predict, will help the air compressor manufacturers predict the problems of customer machines in advance, which will greatly enhance the user experience.

Chennai IOT Cloud Platform

What the Internet of Things means for business

If data is compared to an oil field, then IoT technology is the oil pump that collects the data. The data collected will largely help enterprises to run efficiently and analyze their business processes in depth, helping them to make more accurate real-time decisions. As conveyed in the "14th Five-Year Plan", informationization has brought a once-in-a-lifetime opportunity for the Chinese nation. For traditional manufacturing enterprises, we must seize the historical opportunity of informationization development and use informationization as the core driving force to build new advantages for the new generation of enterprises.

Related news